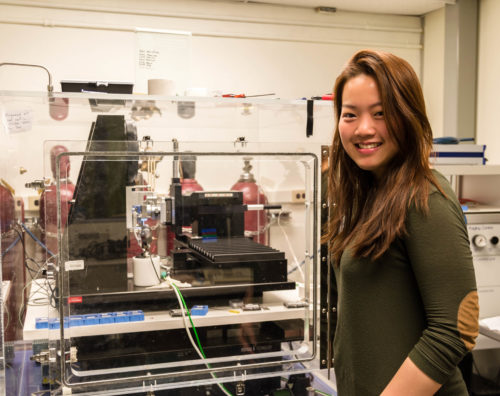

The nuclear materials group has a suite of experimental capabilities to conduct research and training. Some of the tools listed here are unique and are available only at UC Berkeley’s nuclear engineering department. Most of these tools are accessible to external users via the Nuclear Science User Facility (NSUF), since UCB’s nuclear materials group is part of the NSUF network.